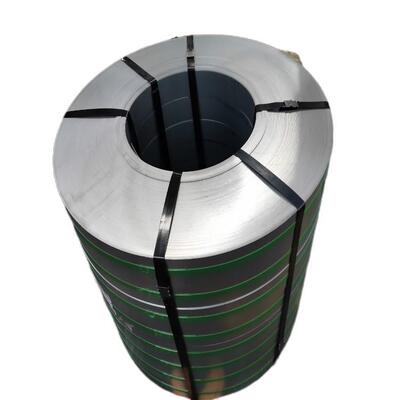

Galvanized Steel Strip

1. Competitive price and quality from our own factory

2. Approved by ISO9001, CE, SGS every year

3. Best service with 7*24 hour’s reply

4. Flexible payment with T/T, 100%LC, etc

5. Smooth production ability (50000tons/month)

6. Quick delivery and standard exporting package

7. OEM/ODM

Product description:

Galvanized strip is a long, narrow strip of cold or hot rolled steel coated in varying degrees with a material called (zinc,aluminum). Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between hot-dip galvanized strip steel matrix and molten bath to form a tight zn-fe alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the strip matrix. Therefore, its corrosion resistance is strong.

Surface:Spangle is formed during the hot-dip galvanizing process. The size, brightness, and surface of spangles mainly depend on the composition of zinc layer and the cooling method. According to the size, it includes small spangles, regular spangles, big spangles, and free spangles. They look different, but the spangles almost will not influence the quality of galvanized steel. You can choose according to your preference and purpose.

Product parameters:

Iterm | |

Standard | AISI, ASTM, BS, DIN, GB, JIS,etc. |

Nominal Thickness | 0.12~4.00mm |

Nominal Width | 20-740mm |

Thickness of Coating | Z60~Z275 |

Coil Inner Dia. | 508/610mm |

Spangle | Regular Spangle/Mini Spangle/Zero Spangle |

Surface treatment | Chromated(Cr6), Chromated(Cr6) and oiled,Cr3 Chromated(Environmental), Cr3Chromated(Environmental) and oiled, Environmental passivated( Chrome free) and oiled, Environmental passivated( Chrome free), oiled, Non-treatment,Skin passed; |

Grade | DC54D+Z,DX54D+Z,SGCD2,DDS, FeP06GZ,St06Z |

Price term | 100%L/C at sight; T/T 30% in advance,70% balance after received B/L copy |

Packing | Mill's standard export sea-worthy packing |

Application | doors or windows of automotive, office equipments,construction, furniture, oil tank; |

Usage | Grade | Yield strength(MPa) | Tensile strength(MPa) |

Punching galvanized steel | DC51D+Z | - | 270-500 |

DC52D+Z | 140-300 | 270-420 | |

DC53D+Z | 140-260 | 270-380 | |

Structure galvanized steel | S280GD+Z | ≥280 | ≥360 |

S350GD+Z | ≥350 | ≥420 | |

S550GD+Z | ≥550 | ≥560 |

Production process:

The production process of cold rolled strip is generally as follows: pickling → rolling → process lubrication → annealing →leveling → cutting → packaging. Cold rolling process: pickling -- rolling -- annealing -- synchronous lubrication of rolling size-- anti-rust oil -- leveling and sizing -- polishing -- packaging

Heating furnace of hot rolled strip steel: - phosphorus removal machine, roughing mill, phosphorus removal machine, finishing

mill, surface quality inspection instrument - layer of cold - reel, baling machine, injection machine - volume base slab.

Characteristics:

1.Long Life-span: With galvanization, a piece of industrial steel is expected to last more than 50 years in average environments, and can last over 20 years with severe water exposure. There is no maintenance required. The increased durability of the steel’s finished product also increases the product’s reliability.

2.Rust Resistance: From the zinc coating. The iron elements in steel are incredibly prone to rusting, but the addition of zinc acts as a protective buffer between the steel and any moisture or oxygen. Galvanized steel is very protective, including sharp corners and recesses that couldn’t be protected with other coatings, making it resistant to damage.

3. Sacrificial protection: The sacrificial anode ensures that any damaged steel is protected by the surrounding zinc coating. It doesn’t matter if the steel section is completely exposed; the zinc will still corrode first. The coating will corrode preferentially to the steel, creating a sacrificial protection to the areas that are damaged.

Transportation & packaging:

We offer high-quality service with 24/7 online support.

Related Products

Submitted successfully

We will contact you as soon as possible

Related News

Submitted successfully

We will contact you as soon as possible